"Understanding Extension Spring Hook Styles: Machine Hooks vs. Side Loops

When it comes to designing extension springs, choosing the right hook style is crucial. In this article, we dive deep into the differences between the two most popular hook styles - machine hooks and side loops. These hooks are widely adopted in sectors like medical, furniture, transportation, and more. Notably, many springs at SPS incorporate both hook styles, tailored to specific spatial and connection requirements.

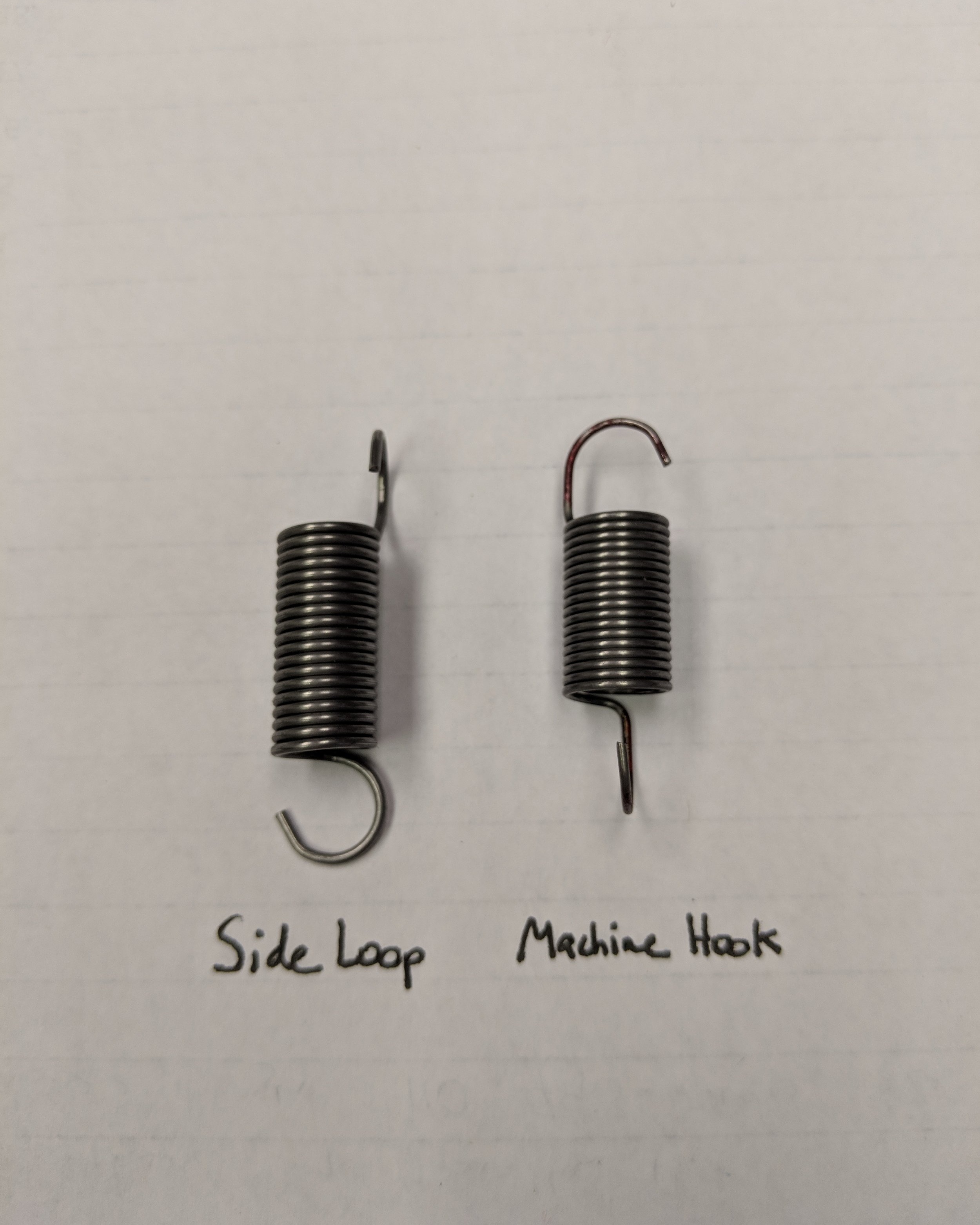

The vast majority of extension springs have two styles of hooks. A hook over center called a machine hook, and a hook over the body on one side of the spring called a side loop. Both styles of hook have gaps and hook heights the only difference is the orientation of the hook.

Breaking it down, extension springs primarily feature two distinct hook styles:

Machine Hook: Positioned over the center, this hook offers a direct, linear transfer of force. Its design promotes efficient force distribution, reducing the chances of stress points.

Side Loop: Positioned over the body on one side of the spring, side loops have a unique orientation. While they come with gaps and hook heights similar to machine hooks, their orientation induces torsional stress at the transition point. This area often becomes a vulnerability if the spring faces excessive stress, leading to potential breakage.

In conclusion, while both hook styles are instrumental in various applications, understanding their dynamics can help in optimizing spring performance and longevity."

Side Loop Extension Spring pulled to a load point. Notice the first coil on the top and bottom.

Machine Hook Extension spring pulled to a load point.